Adhesive are materials used to join objects together. Various adhesives are available for different purposes.

Daily-used adhesives can be classified into two main types:

(Fig. 38)

(Fig. 39)

(Fig. 40)

(Fig. 41)

| Non chemical reaction type | Chemical reaction type | ||||||

| Type | Features and products | Type | Features and products | ||||

| Let-dry type | * with volatile solvent, sets when vaporized. (Fig. 38). Suitable for paper and wood. * contains polyvinyl acetate (white glue), (Fig. 39). Excellent for gluing paper. | (epoxy-resin) | A+B (without filling) | A part and B part mixed together in the ratio of 1:1. Need to stir the two liquids at least ten times to make them completely mixed. Will form a very strong and clear thermosetting polymer. A first choice for stronger adhesive than contact glue. Rapid type (5 mins) , normal type (1 day). “Araldite” (Fig. 45) is a well-known brand.

| |||

| Press-type | Clear Scotch tape, (Fig. 40) stick strip (Fig. 41). Need to press for sticking. | ||||||

Contact- type | Powerful adhesive, need pressing, for general use. Especially useful for adhering Formica sheet or wooden parts. (Fig. 42). | A+B (with filling) | A part and B part mixed together in the ratio of 1:1. Need to roll, rub and scour repeatedly for at least ten times to make the two parts completely mixed. Will form a very strong and opaque (grey) thermosetting polymer. Adhesive power much stronger than the without filling model. Sets even under water. Commonly known as “steel cement”, the best for metal bonding. Rapid type (Fig. 46) and normal type (Fig. 48) are available. One commercial brand is in the form of a “banana roll” embedded coaxialy with A part and B part (Fig. 47) separately. Cut the roll into pieces and rub. | ||||

| Fast-dry type | Collectively known as AA (Aron Alpha) glue. Exceptionally fast drying (Fig. 43). Basically, it contains the monomer cyanoacrylate. When exposed to air’s moisture, it will undergo anionic polymerization, liberates heat and sets instantaneously, bonds both surfaces with great force. AA glues works beautifully with smooth surfaces, like glass, and bonds them permanently in seconds. Avoid contacting it with hands.

| ||||||

| Hot glue type | Hot glue gun melts glue stick and sets to join parts together. (Fig. 44). A common tool for handcraft workshops. | ||||||

(Fig. 42)

(Fig. 43)

(Fig. 44)

(Fig. 45)

(Fig. 46)

(Fig. 47)

(Fig. 48)

Please view the following video clip for laminating Formica sheet with wooden objects:

Professional adhesives

Usually refer to “plastic glass adhesive” and “liquid nail”.

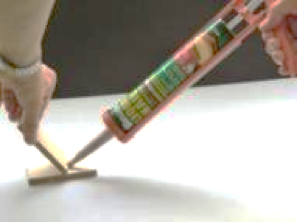

This kind of adhesives need to work with a “pump gun” (Fig. 49):

Laminating formica sheet

(Fig. 49)

(i) Plastic glass

As its name implies, plastic glass is mainly used for cementing glass plates. Normally, the glass plate to be bonded has to be arranged perpendicularly e.g. fish tank. One point needs to be noted: water or liquid is different from solid with respect to exerted pressure. water and liquid can exert side-way pressure as well as top-down pressure. Water having a density of 1.0 gcm-1 is much greater than that of paper or wood. Hence professional assessment of thickness and strength is required when constructing a fish tank by cementing glass plates.

The full name of plastic glass is silicone plastic sealant. It looks like hand cream, when contacting air, air’s moisture will solidify it to form a tough rubber-like sealant. Exceptionally good for glassware. Silicone sealant is classified as (i) acidic (de-acidified) type or (ii) neutral (de-alcoholic) type. Acidic type itself is not acidic, but on solidification when exposed to air, consumption of moisture releases irritating acetic acid. Neutral type, on the other hand, releases non-irritating alcohol. Acidic plastic glass sets faster but causes metal corrosion. Neutral plastic glass sets not as fast as the acidic counterpart, but has better binding power. However, its ductility and malleability are at a disadvantage.

Plastic glass is generally used for patching gaps and slits (Fig. 52). In the past, acidic sealant is commonly used (Fig. 50). Nowadays, neutral sealant is more popular (Fig. 51).

(Fig. 50)

(Fig. 51)

(Fig. 52)

(ii) Liquid nail

Physically speaking, liquid nail (Fig. 53) is not a nail. It is a powerful glue especially good for joining wooden objects. Liquid nail is just an analogy for its function like a nail. It is widely used in construction work. Apart from its outstanding binding power, unlike stiff epoxy steel cement, its soft, tough and durable nature enables it especially suitable for site work. Australia’s “Shelley’s” liquid nail (澳洲犀利牌) (Fig. 54) is a well-known brand.

(Fig. 53)

(Fig. 54)