Commonly used raw materials include: 1. Plastics and products, 2. Aluminium and products, 3. Copper/brass and products, 4. Wood and products, 5. Glass and products.

1. Plastics and products: a. Acrylic sheet (North America call it plexiglass), tubing and strip; PVC sheet and tubing.

(Fig. 55) Amber acrylic sheet and clear tubing

(Fig. 56) PVC sheet and tubing

All acrylic sheets have a protective cover which should be peeled off before use (Fig. 55). Acrylic sheets come with various colours, clear and transparent type is largely used. PVC sheets do not have such protective membrane (Fig. 56). They are usually grey and opaque. PVC tubings are either grey or white.

a. Acrylic sheets, tubing and strip

(i) Gluing acrylic sheets, tubing or strip

The most suitable glue for acrylic is trichloromethane (chloroform). Inject, with the help of a syringe or a micro-pipette, one drop at a time, small amount of trichloromethane between the junction point of two acrylic sheets (Fig. 57). Hold the parts tightly, wait for a while until the glue penetrates the slit completely. Repeat the procedure at least 3 times. The two acrylic parts will join tightly after a few minutes (Fig. 58). Gluing power is excellent because the plastics dissolves in the glue (as solvent) and the two parts are joint together as the same kind of material upon evaporation to dryness. Has to be done quickly as trichloromethane is very volatile.

Advisable to wear facial mask.

Gluing acrylic sheets or tubings

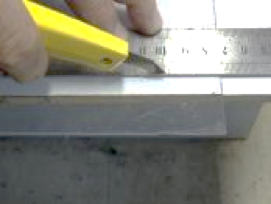

(ii) Cutting acrylic sheets

Sheets more than 1 mm thick should be sawn. Acrylic sheets 1 mm thick or less than can be cut into half by the following method: First buy a special cutter designed for cutting acrylic sheets (Fig. 59). Peel off the protective cover, make a deep scratch as shown in (Fig. 60). Place the assembly near the edge of the bench (Fig. 61), protruding the part to be cut. Make a sharp blow with one hand by chopping down (Fig. 61). The protruded part will come off nicely.

Hand cut acrylic sheets

(Fig. 57)

(Fig. 58)

(Fig. 59)

(Fig. 60)

(Fig. 61)

(Fig. 62)

(iii) Bending acrylic sheets

Lay the plastic sheet over a nichrome wire heated to red hot until the heated part softens (Fig. 62). Hand bend it to the required shape (Fig. 63).

b. PVC sheets and tubing

(i) Gluing PVC sheets/tubing:

A special glue for gluing PVC plastics is available (Fig. 64). This glue does not work with acrylic plastics. Although not volatile, it has irritating smell and advisable to wear facial mask. A couple of hours is required for complete setting.

(ii) Bending PVC sheets: Like acrylic sheets, bending of PVC sheets need also heating by a hot nichrome wire.

A DIY acrylic sheet bender

(Fig. 63)

(Fig. 64)

(Fig. 65)

2. Aluminium metal and products: Although the tensile strength of aluminium is not as strong as that of steel or brass, its decent ductility is at an advantage though. Thin sheets can be cut with large cutters (Fig. 65). Thick ones should be sawn (fig. 66). The covering oxide layer enables aluminium surface resistant to corrosion. The metal is an ideal construction material for instrumental cases. A point worth noticing is that aluminium cannot be soldered.

3. Copper/brass and product: Brass sheets or tubing is another good choice of material for instrument construction. Advantages included: can be soldered easily, good tensile strength and decently resistant to corrosion. Costs a bit higher than aluminium. Pure copper sheets are very flexible, easy formation by simple bending (Fig. 67). Copper is the second-best metal for soldering purposes as well as electrical conductivity. Not available in hardware stores, obtainable from copper raw material or scientific companies.

(Fig. 66)

(Fig. 67)

(Fig. 68)

(Fig. 69)

(Fig. 70)

(Fig. 71)

4. Wood and products: Carpentry planks are seldomly available, instead most timber shops sell plywood. Wood saw (Fig. 69) is used for sawing (iron saw is equally good). Apart from nailing, the following methods can be used to permanently join wooden objects together:

(i) Apply hot glue to the joining point and then do the nailing (Fig. 70, 71). Hot glue sets quickly and the wooden parts are permanently joined.

(ii) Similar procedure as (i), but use liquid nail instead (Fig. 72). Takes longer time to set but offers even stronger sealing.

5. Glassware: Glassware formation is a highly skillful job, only professionals can accomplish. Common laboratory glassware like beaker, test tube or measuring cylinder are available commercially, there is no need to home make them. The often-encountered situation with glassware is to cut, join or bend glass tubings.

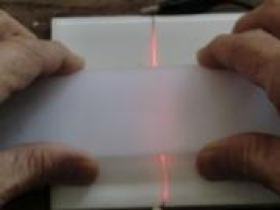

Using a small triangular file or diamond cutter, make a deep scratch round the glass tube (Fig. 73, 74). Facing the scratch up, apply with both hand a small but subtly suitable force (thumbs up but rest of the fingers down, Fig. 75), a ”click” sound means the tubing has been successfully separated (Fig.76). Broken end of glass tubing is dangerously sharp and there is a need to make it smooth and manipulable. “Fire polishing” is the common method. First warm the sharp end with a yellow Bunsen flame (or butane torch), then strongly heat it to red hot (Fig. 77) for a minute or so, the glass starts to melt and make the end polished. Sudden withdrawal of flame is highly not recommended because this will cause cracking due to rapid lowering of temperature. What one needs to do is to return the flame to yellow (less hot) for a couple of minutes and then remove the finished product from the flame. This procedure is technically known as “Tempering (回火)”.

(ii) Joining glass tubings

Joining glass tubing using compressed air torch requires professional skill and is beyond the scope of the DSE syllabus. A commonly used method of joining glass tubings is to use a segment of rubber (or silicone) tubing.

Cutting glass tubing

(Fig. 72)

(Fig. 73)

(Fig. 74)

(Fig. 75)

(Fig. 76)

(Fig. 77)

Summary

| Material | Usage | Remark |

| Plastics and products | Acrylic sheets First choice for medium supporting strength Sheets are more popular than tubings First choice for insulating material PVC sheets Not commonly used for large area work PVC tubings (pipes) are more popular than sheets First choice for insulating material | Acrylic sheets Trichloromethane is the only glue. Softens at high temperature. Cannot apply heat Cannot work with organic substances PVC sheets Use PVC glue Softens at high temperature More flexible than acrylic sheets Cannot work with organic substances |

Aluminium and products | First choice for high supporting strength construction materials Sheets and varieties of tubings are both popular | Cannot be soldered Fixed by screw/nut combination or rivets |

Copper/brass and products | Brass Tubings are more popular than sheets Position of copper is below hydrogen in the reactivity series, not readily corroded (than iron or zinc). No observable change with water or organic solvents. Refer to Program (2) topic (3.1) Micro-scale distillation set for a practical example of use. Pure copper The advantage of pure copper is its flexibility. It can be easily mamipulated to various formations. Copper reacts slowly with air’s CO2 to form green CuCO3, appears mostly in roof tops of ancient buildings. Conductivity of copper is just after silver the champion, but much less expensive. Copper wires are used in all kinds of conducting cables. | Both copper and brass can easily pick up molten solder. Both are safe to handle. Both are good conductors of heat, safeguard against scalding. These metals have sharp edges, beware of cut injuries. |

| Wood and products | Wooden materials are common, not expensive and can form various shapes easily. Wooden materials can be used for general designs. Not recommended to use too thin plywood. Second choice as an insulator. | Can catch fire |

| Glassware | Transparent and can withstand very high temperature. Unfortunately, it is brittle and can be broken easily. All glassware can contain organic/inorganic solvents. | Naked cut edges of glass are dangerously sharp. Handle with great care (fire polishing). |